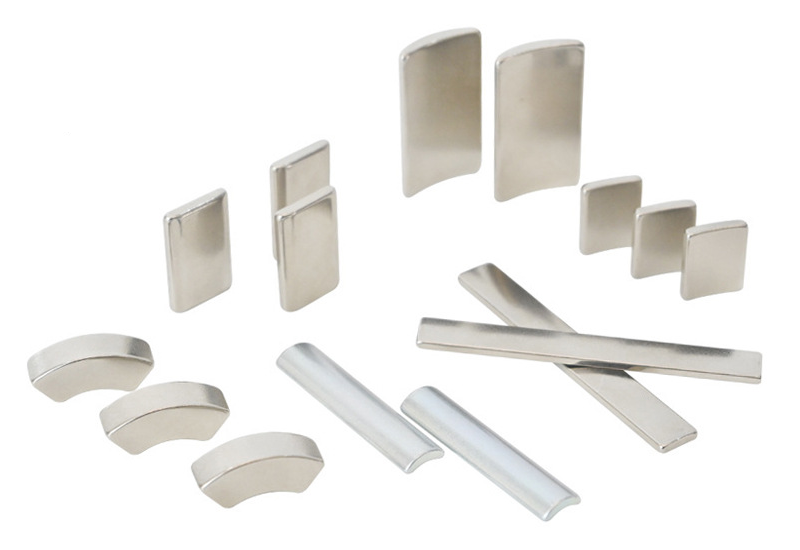

YuYue Magnets carries a large inventory of permanent rare earth magnet materials. Rare earth magnet materials have magnetic properties far exceeding those of ceramic or Alnico materials, making them the magnetic material of choice for many technical applications. We offer off-the-shelf rare earth magnets in standard sizes, shapes and grades, or custom magnet configurations made to order.

YuYue Magnets carries a large inventory of permanent rare earth magnet materials. Rare earth magnet materials have magnetic properties far exceeding those of ceramic or Alnico materials, making them the magnetic material of choice for many technical applications. We offer off-the-shelf rare earth magnets in standard sizes, shapes and grades, or custom magnet configurations made to order. Neodymium Iron Boron (NdFeB) magnets are part of the rare earth magnet family, and are extremely powerful and versatile. Components that were once large and heavy by necessity, can now be miniaturized by using these permanent magnet materials. This often results in a substantial cost savings for the completed magnet assembly. High in strength and less brittle, but more temperature sensitive than the SmCo types of rare earth magnets, neodymium magnets are often the more cost effective choice.

Neodymium Iron Boron (NdFeB) magnets are part of the rare earth magnet family, and are extremely powerful and versatile. Components that were once large and heavy by necessity, can now be miniaturized by using these permanent magnet materials. This often results in a substantial cost savings for the completed magnet assembly. High in strength and less brittle, but more temperature sensitive than the SmCo types of rare earth magnets, neodymium magnets are often the more cost effective choice.

Samarium cobalt magnets (or SmCo magnets), also part of the rare earth magnet family. These high-performance magnets are extremely powerful and available in different grades that span a range of properties and application requirements. SmCo magnets have a very high resistance to demagnetization and to corrosion. They exhibit excellent temperature stability, and can operate at temperatures up to 525°F (300°C).

Samarium cobalt magnets (or SmCo magnets), also part of the rare earth magnet family. These high-performance magnets are extremely powerful and available in different grades that span a range of properties and application requirements. SmCo magnets have a very high resistance to demagnetization and to corrosion. They exhibit excellent temperature stability, and can operate at temperatures up to 525°F (300°C).